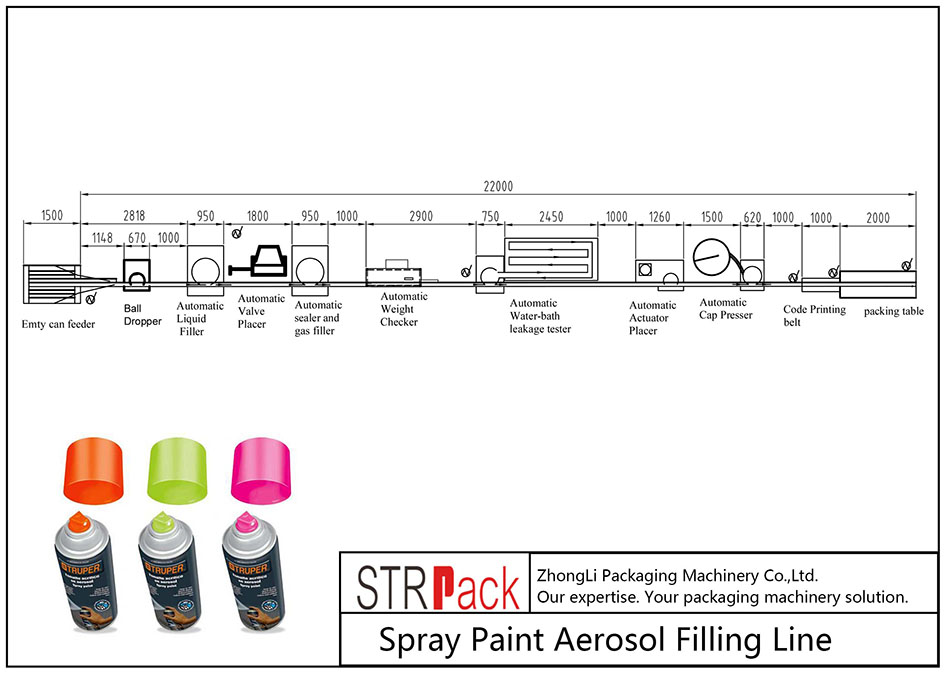

Automatic Spray Paint Aerosol Filling Line

Automatic Spray Paint Aerosol Filling Line

Filling Line Details

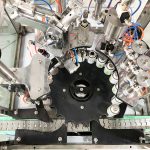

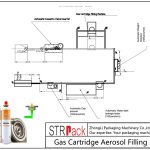

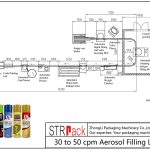

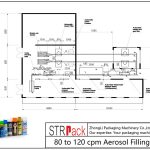

Automatic Spray Paint Aerosol Filling Line is the most typical and popular automatic aerosol filling line for spray paint. Automatic spray paint aerosol filling line consists of Automatic Ball Dropper, Automatic Aerosol Filling Machine, Automatic Valve Placer, Automatic Checkweigher, Automatic Actuator Placer, Automatic Cap Presser.

It adopts screw can sorting device to avoid can jam and full cover nozzle to avoid paint pollution on can. Easy cleaning is available for paint color changing by fast assembly cylinder.

It’s suitable for can diameter ranging from 35mm to 65mm, can height ranging from 80mm to 330mm, 1” international standard aerosol valve. Easy and convenient in operation & maintenance. It’s the best choice for automatic spray paint aerosol product production to reach 2,400-3,000 cans/hour.

Machines Included:

· Automatic Aerosol Filling Machine

· Automatic Ball Dropper

· Automatic valve inserter

· Automatic Weight Checker

· Automatic Water-bath Leakage Tester

· Automatic Actuator Placer

Technical Specifications

| Product filling capacity | 50-750ml |

| Product filling accuracy | ≤±1% |

| Glass ball feeding mode | By gravity |

| Diameter of glass ball | ø12mm, ø16mm, ø20mm etc. |

| Ball filling number | 1-4 pcs |

| Propellant filling capacity | 50-750ml |

| Propellant filling accuracy | ≤±1% |

| Valve sealing accuracy | ≤±1% |

| Production capacity | 2,400-3,000 cans/hr |

| Working pressure | 0.65-1Mpa |

| Maximum air consumption | 3m³/min |

| Applicable aerosol can diameter | 35-65mm |

| Applicable aerosol can height | 80-330mm |

| Aerosol valve requirement | 1” international standard aerosol valve |

| Power supply | 380V or per customer’s specification |